Environment

‘’We operate responsibly, following a holistic preventive approach to addressing environmental challenges, incorporating and applying principles of Sustainable Development in all of our operations.’’

Environmental protection is one of the Company’s key priorities. We are promoting environmental responsibility as an integral part of our corporate philosophy, having incorporated the responsible and effective management of environmental issues related to our activity into our strategy. Implementing a number of practices, processes and control systems, Halcor manages its environmental impacts in a systematic, complete and effective manner. Halcor’s management is committed to providing all the necessary means and resources to allow a rational and integrated management of environmental issues.

Environmental protection

Respect and care for the environment are a common denominator in all our activities.

Sustainable Development Goals

Our commitment for the environmental protection.

Environmental protection is a duty for ElvalHalcor, so we take care that our business operations are environmentally responsible. We seek to prudently and rationally manage environmental issues associated with ElvalHalcor’s activity, implementing a series of practices, procedures and control systems. In order to reduce our environmental footprint, we:

- implement targeted environmental management plans (e.g. energy saving plans, actions and initiatives to reduce air emissions, etc.).

- seek the rational use of natural resources and we promote copper and aluminium recycling.

- implement an integrated waste management system built on the principles of the Waste

Management Hierarchy and on the adoption of best practices aiming to prevent their generation.

- make continuous investments on environmental protection infrastructure.

- focus on continuous training and raising awareness of our employees and partners in environmental matters.

Policy and Systems.

We have established and implement an environmental policy that reflects ElvalHalcor’s overall approach to protecting the natural environment (http://www.elvalhalcor.com/en/sustainability/environment/). In order to implement the policy and achieve its objectives, we apply a certified Environmental Management System (in accordance with the requirements of the international standard ISO 14001: 2015) in all ElvalHalcor ‘s production facilities.

Our constant goal is the continuous reduction of our environmental footprint. To achieve this, we focus on key issues such as:

- preserving natural resources

- rational raw material management

- minimising emissions/ greenhouse gas emissions

- rational waste management

- increased reuse of materials.

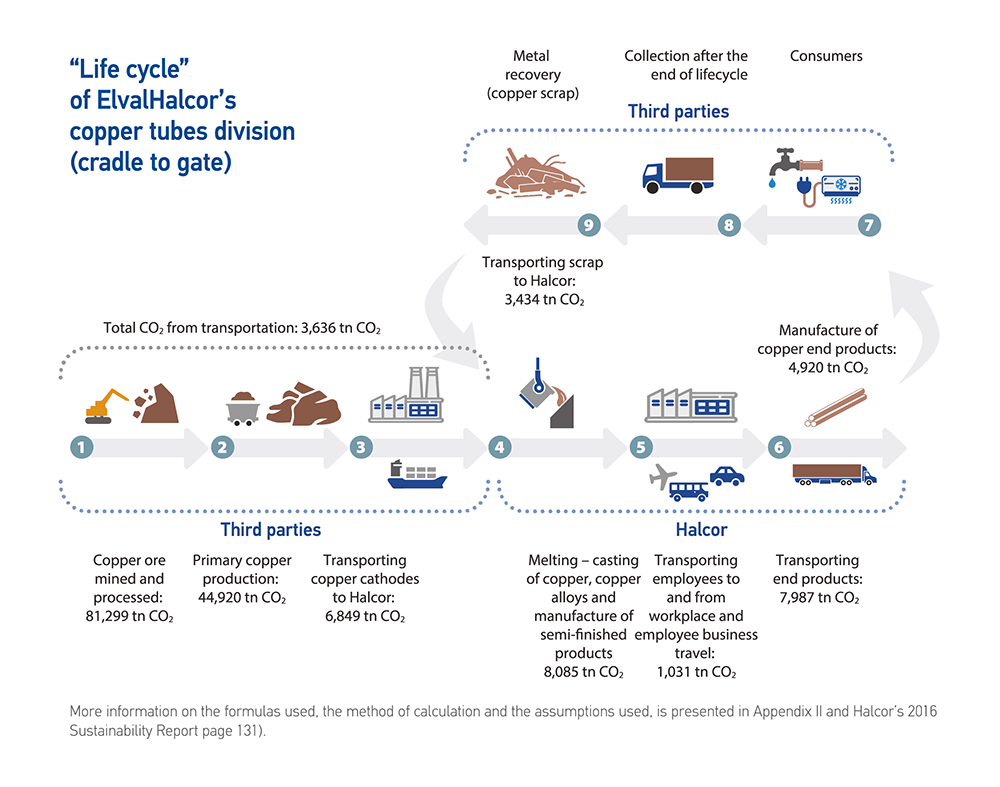

Using scrap and promoting aluminium and copper recycling.

The Company’s primary raw materials are aluminium and copper. As the benefits of scrap use are significant (reduction in energy consumption, greenhouse gas emissions and water use), we focus on practices that maximise the efficient use of raw materials and scrap. In collaboration with its customers, mainly from the packaging sector, ElvalHalcor promotes and actively implements the principles of the circular economy, constantly increasing, in the production of new products the use of aluminium and copper that comes from collecting products at the end of their life cycle. Recycled scrap accounted for 58.7% of the metals used in the Copper tubes division’s production process.

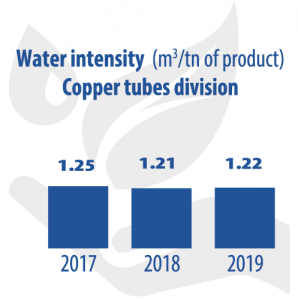

Water management.

ElvalHalcor seeks to conserve water and is constantly focusing on water conservation practices. Water reuse practices are applied in our production process whenever possible. The water consumed by the Company comes entirely from the EYDAP water supply network (the Copper tubes division obtains a very small quantity from the Oinofyta network).

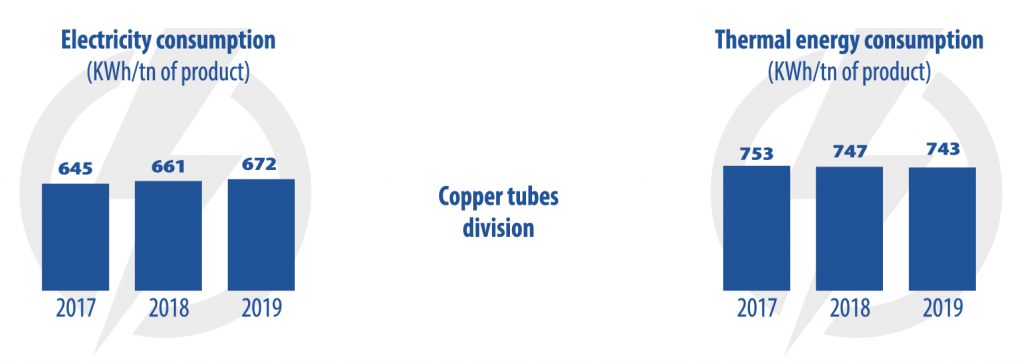

Energy consumption.

To continuously improve the energy performance of its entire business, ElvalHalcor applies a certified Energy Management System in accordance with the requirements of the international standard ISO 50001:2018. We constantly invest in state-of-the-art technology equipment and energy saving projects, while seeking to rationally use fuel and improve energy efficiency. In 2019, upon request, ElvalHalcor was issued, by the Regulatory Authority for Energy (RAE), a license to build a new power plant. The plant will run on natural gas, will have a capacity of 566 MW and will be built in Thisvi, Viotia, with an estimated investment cost of EUR 300 million. ElvalHalcor is currently in the licensing process for the plant in Thisvi but, on the other hand, is not focusing only on this option.

In 2019, the Company took, among others, the following actions for reducing energy consumption in the Copper Tubes Division:

- Repairing leaks in the air compressor room, with annual savings of 3,245 MWh.

- Operating with smaller cross-section coils in the continuous annealing induction furnace (ELPHIAC 2). The tests have been completed. A reduction in consumption from 23 to 18.5 KWh/km is expected.

- Networking of energy meters and installation of measurement and reporting software. The installation of the software and hardware has been completed and user training, along with the creation of report and control charts, is in progress.

- Purchasing a 850KVA dry type transformer with PF energy efficiency> 99% and in compliance with ecodesign 548 / 2014PF. Annual savings of 23.2 MWh.

- Installing in 6 new storage tents 108 luminaires controlled by motion and light sensors, with annual savings of 29.9 MWh.

- Installing a continuous annealing line adjusted to dimensions <9.85mm outside diameter, with annual savings of 52.5 MWh.

- Installing fluorescent tubes in the «N» building and roof repair, with annual savings of 39 MWh.

- Installing an air flow meter at the Genevet filter outlet to optimise its operation (avoid idle operation).

- Installing a PLC controller to adjust and optimise the operation of cooling tower fans, with annual savings of 90 MWh.

Circular economy and waste management.

Europe’s transition to a circular economy is a key strategy of the European Commission, with dozens of agencies working together through major international programmes (LIFE, Horizon 2020, etc.). One of the most important aspects of this strategy is «Closing the loop», i.e. the conversion of waste again in raw material or, if this is not possible, its use as fuel for energy production. This not only limits the environmental impact of a product but, also, the raw material and energy recovered from it replace production needs.